Amerispray Atomizing Nozzles

UNI-SPRAY offers a wide rage of ATOMIZING NOZZLES as well as complete HUMIDIFICATION SYSTEMS.

Applications:

humidification

food processing

paper manufacturing

snow making

textile industry

steel production

chemical coating

pharmaceutical industry

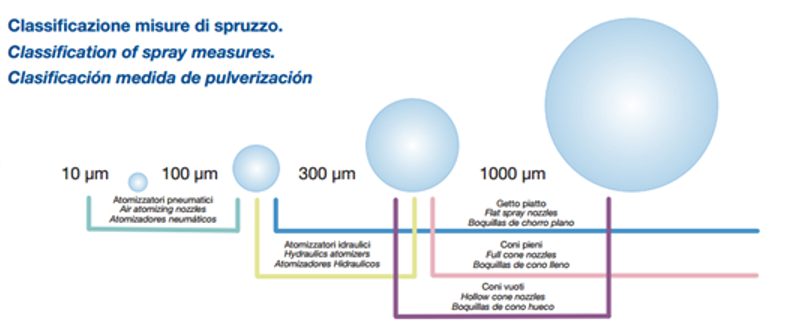

Atomizing nozzles produce a much finer spray than standard spray nozzles and fall into three main categories:

*median droplet sizes relative to minimum and maximum capacity values at 3 bar pressure

HYDRAULIC ATOMIZING NOZZLES use medium to high hydraulic pressure to produce a very fine spray in a hollow cone pattern (less spray in the middle). As pressure increases, droplet size reduces.

PNEUMATIC ATOMIZING NOZZLES mix compressed air (or other gas) with liquid to achieve very fine nebulization at relatively low pressures (3 bar or less). Spray patterns are either full cone, hollow cone or flat, depending on the caps used. Automatic air atomizing nozzles (P series) deliver controlled intermittent spraying at more than 100 cycles per minute. Mixing is either internal or external, and liquid is fed to the nozzle by pressure, siphon or gravity, depending on set-up.

Internal Mixing

Liquid is mixed with air inside the nozzle, the combination of air and liquid pressure influencing the nature of the spray achieved. Available spray patterns:

• Full cone

• Hollow cone

• Flat jet

Outside mixing

Liquid is mixed with air outside the nozzle. Outside mixing is ideal when liquids are highly viscous or dense or contain very small solid particles.

Available spray patterns:

• Flat jet

• Full cone

ULTRASONIC ATOMIZING NOZZLES use a resonator at the nozzle opening to produce the finest atomization on the market.